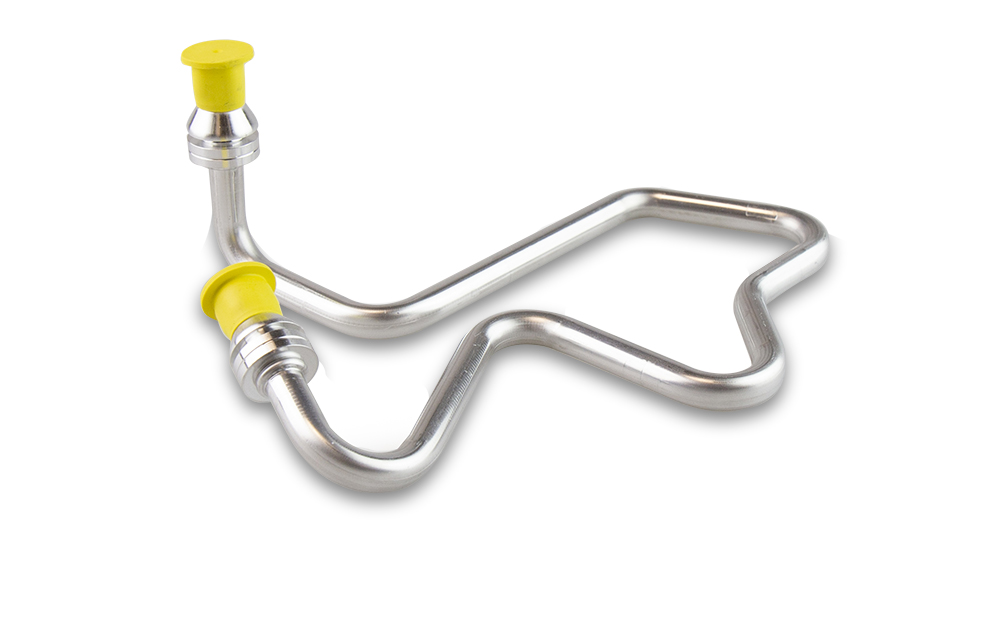

MEDIA CARRYING LINES

TUBES AND TUBE SOCKETS

Automotive

TUBES AND TUBE SOCKETS

TUBES AND TUBE SOCKETS ARE PRODUCED IN NEARLY ANY FORM ACCORDING TO CUSTOMER REQUIREMENTS AND DRAWING

Function:

Tubes in thermal management are versatile transport elements for different media.

Description:

In the following applications tube material is used for thermal management: Cooling of power electronics, oil management modules, batteries, fuel cells, brake and fuel lines, air conditioning, control lines and steering systems.

ADVANTAGES

- High energy efficiency

- Cost effective manufacturing

- Wide range of variants and dimensions can be produced

- Use of special forming tools for tube sockets

- High level of application knowledge that can be transferred to tube design

- Simulations

INNOVATION

- Development of a solderless tube- socket geometry

- Development of materials for special applications (tube in aluminum casting)

- Development of laser joints

- DMC laser coding

- Tolerance consideration in relation to bending and end forming tools

- Design for tube and material in relation to cooling of assemblies

PRODUCTION

- In-house mechanical engineering supports automated production processes and manufactures special solutions

- In-house prototype construction

- In-house process and development

- Extensive laboratory facilities for the development of innovations