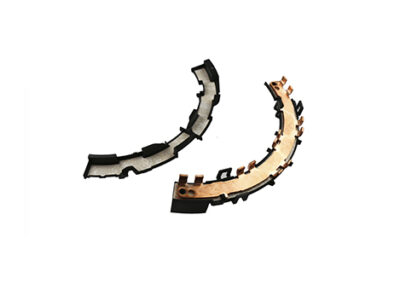

plastic / plastic metal combinations

WHEN PLASTIC, METAL AND ELECTRONICS ARE MERGING

Automotive

plastic / plastic metal combinations

WHEN PLASTIC, METAL AND ELECTRONIS ARE MERGING

Function:

The perfect fit between plastic and metal creates components that combine the advantages of both materials.

Description:

Insert and outsert technologies are used to manufacture hybrid components from plastic and metal using injection molding processes.

ADVANTAGES

- Off-tool production of high-performance components by combining different material categories without further processing.

- Synergy effects and functional integration by exploiting the advantages of the materials used, especially in terms of mechanical properties and electrical conductivity.

- Weight and cost reduction.

- High automation level possible.

INNOVATION

- In-house production of metal and plastic parts (complete component from a single source).

- Development and numerical simulation of components and processes.

- FEM aided design.

- Integrated process approach as Full Service Supplier.

- High competence in automation thanks to in-house machinery department.

PRODUCTION

- Plastic injection molding on vertical and horizontal machines.

- Processing of various high-performance technical plastics filled and unfilled, conductive and insulating, as well as GF and LGF reinforced. Flame resistant plastics.

- Overmolding and backmolding of metal inserts

- Production of stamping and bending parts

- Surface coating.

- Subsequent complementation to assemblies.

Automotive

METAL SUBSTITUTION

Components from metal are replaced by plastic parts.

Function:

Components from metal are replaced by plastic parts.

Description:

Through the use of high-performance technical plastics, components with high physical properties in terms of strength, stiffness and temperature resistance are produced.

ADVANTAGES

- Weight and cost reduction.

- Improved freedom of design.

- Higher output quantity of the tools than it is the case with aluminum or magnesium – high-pressure die-casting.

- No corrosion of components.

- Wide / optimized property profile possible due to additives

- Function integration through technology – assembly set.

INNOVATION

- Optimal component design by mastering plastic and metal materials.

- Development and numerical simulation of components and processes.

- High competence in automation.

PRODUCTION

- Plastic injection molding.

- Processing of various high-performance technical plastics filled and unfilled, conductive and insulating, as well as GF and LGF reinforced. Flame resistant plastics.

- Subsequent complementation to assemblies.

Automotive

PLASTIC

The components serve as housings or functional parts within assemblies.

Function:

The components serve as housings or functional parts within assemblies.

Description:

Production and procurement of plastic injection molded parts, which are required for the assemblies manufactured in the company.

ADVANTAGES

- Weight and cost reduction.

- Function integration.

- Plastics provide good insulation against electricity and heat.

- Combination of different technologies is possible.

- High automation level is possible.

INNOVATION

- Development and numerical simulation of components and processes.

- High competence in automation.

PRODUCTION

- Plastic injection molding in single and multi-component technology.

- Processing of all common plastics.

- Subsequent complementation to assemblies.